DG Series High-Speed Centrifugal Spray Dryer

Working Principle

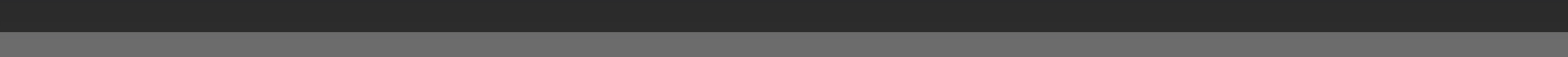

Air enters into hot air distributor “3” at the top of drying chamber though filter “1” and heater “2”, hot air goes into the drying chamber “4” uniformly in spiral state. Liquid material is pumped by pump “6” to the centrifugal spayed “7” after flowed through filter “5”, where it is spayed into fog drops and further contacted with hot air in large surface, and dried into granulate products in a very short time thanks to speedy evaporation of the humidity, humid waste air is accumulated at the bottom of tower by spiral separator “8” and exhausted to the outside by blower “9” .( see dry drawings)

Characteristics and application

High speed drying, Liquid material is centrifugally sprayed at a large surface, 95-98% water content is evaporated instaneous in the high temperature air flow, it only takes a few seconds to finish the whole drying.

Applicable for heat sensitive materials, liquid drop flows in a parallel direction with hot air, high temperature of hot air won’t causes overheat to materials during water evaporation, temperature distributions inside the tower is showed in the following. Wide application.

It’ s widely adopted for Product of a various materials with different physic nature, for instance, polymerid and resin, dyeing-material and color material, ceramic and glass, rust remover and pesticide, hydrocarbon, milk products, blood and fish products, fertilizer,

organic and organic compound etc.

Good dispersiveness, fluidity and dissolubility of the product. Homogeneous fine granulate of the product can be rest assured by the instantaneous drying process.

Simple process and convenient operation, solution with 40-60% humidity (90% is possible for special materials) can be dried into power product in one step, to which, pulverization and screen are unnecessary, this purity of the product is improved at fewer process, size/bulk density and water content of the product can be easily adjusted and controlled in a certain limits according to change operation conditions, meet(GMP)standards.

Order notes

Name and physical property of liquid material: solid content (of humidity), viscosity, surface tension, PH value. Powder material unit weight, tolerated residue water content, size and highest temperature. Output, daily working period.

Power supply: steam pressure, electrical capacity, fuel gas, oil, coal available.

Control requirement: automatic control to the temperature at both end is required or not.

Powder collection requirement: bag type accumulator is needed or not, environmental requirement to tail gas exhaust.

Other special request.

Drying Flow Chart

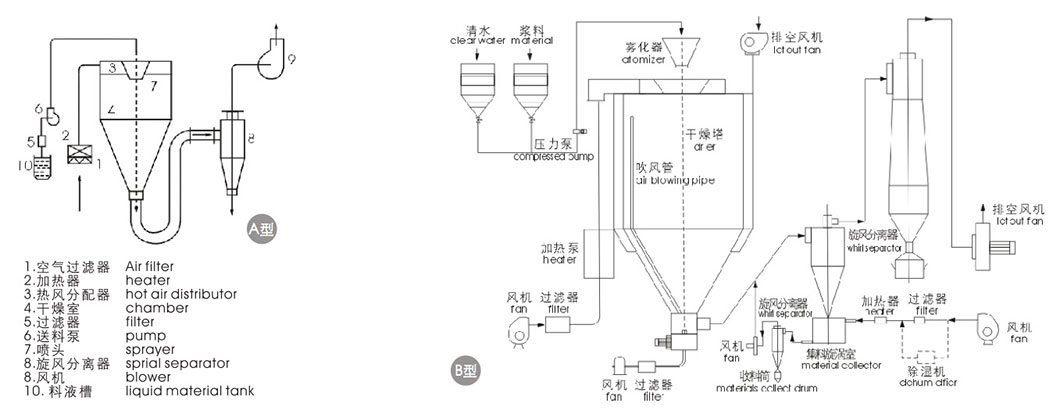

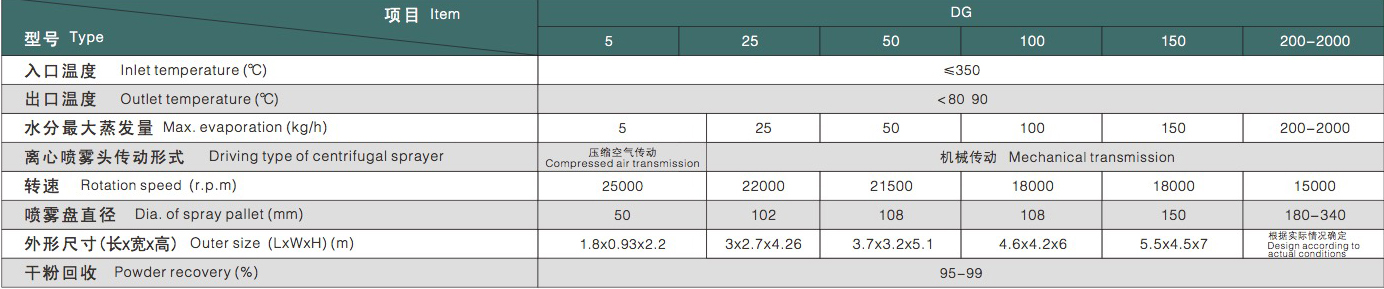

Technical Parameter

Contact us

Email: [email protected]

Add.: No. 367 Yangle Road, Shanyang Town, Jinshan District, Shanghai, China 201508