BG Series High-Efficiency Intelligent Coating Machine

Use

BG Series High-Efficiency Intelligent Coating Machine can be widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc. In such fields as of pharmaceutical, food and biological products etc, and it has following characteristics such as good appearance in design, high efficiency, low energy consumption and in accordance with GMP.

Working Principle

The tablets make complicated and constant track movement with easy and smooth turn frequent exchanging in a clean and closed drum of the film coating machine under the action of guide plate. The coating mediums mixed in the mixing drum are sprayed on tables by the spraying gun at the inlet under the action of the peristaltic pump. Meanwhile under the action of air exhaust and negative pressure 100000 clean hot air supplied by the hot air cabinet is exhausted from air exhaust cabinet and exhaust pipeline, going through tablets and bottom sieve mesh. So these coating mediums on the surface of tablets get dry forming a coat of firm, fine and smooth film. The whole process is finished under the control of PLC, meet (GMP)standards.

Main Structure

1. Main Machine: During the film coating process in the major machine, it shows such features just as no dust fly off and no syrup splash, operation condition improvement, little cross contamination to tablets, simple coating process, coating time shortening as well as high Product efficiency etc.

The main machine adopts programmable controller(PLC)and touch screen system, which can adjust inlet air temperature, rotational speed and other technological parameters automatically, making no difference between various batches products with the same technical parameter.

2. Hot air cabinet: Firstly, air inhaled in through the centrifugal fan should be purified up to the 100000 Level after three times filtration, involving primary filtration, medium filtration and high filtration, then be heated by heat exchanger(steam or electric heating), finally, be blown to the drum of main machine to dry the tablets, the noise of which is less than 70 decibel.

3. Air Exhaust Cabinet: Used for pumping air out of drum from the main machine, making the working area under the negative pressure and equipped with filtrating device, dust removal system and dust collecting system. The operating noise of the whole cabinet is less than 90 decibel.

4. Air spray system: The system is made up with peristaltic pump, air spray gun (imported from Japan) and material connecting line, used for atomizing coating mediums. When coating sugar film, it should be equipped with the dropper.

5. Electric heating thermostatic stirrer: It is used for preparing the film coating mediums, composed by liquid touchable plate, electrical heating system, pneumatically motorized stirring system and so on, meet(GMP) standards.

Performance and Characteristics

All operations can be finished through pushing the touch key on the computer controlled panel, with reliable and stable performance.

The streamline guiding-type mixer drives tablets to make easy and smooth rotation without fragment and chipped edge which improves the yields. The guiding sheet has a narrow surface, to which no dressing can be stuck, economizing on dressing and improving the quality of finished products.

Select the imported spray gun. It’s convenient to operate and easy to master and flexible controlled technological requirement. The spray gun head requirement must keep in the range of 0.29 Mpa to 0.39 Mpa, with adjustable angle and sector, and with such features just as uniform particle, uniform

atomization, large spray area, no dropping leakage, no blockage, dressing economized etc, which is well reputed by the user.

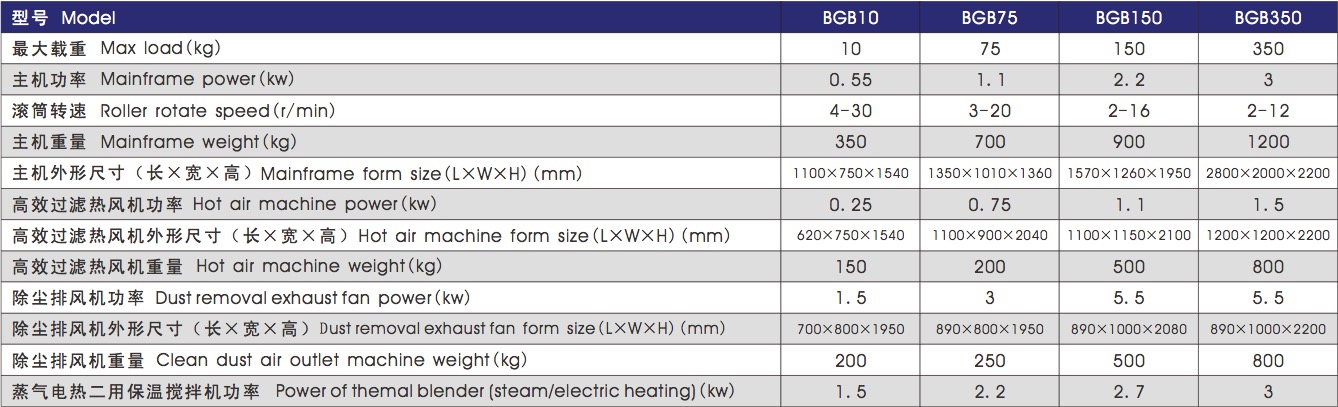

Technical Parameter

With the particular out take adjusting device of the roller inside, easy to solve the problems of the big pot coating for the small quantity material.New style seal structure, and better the leak tightness and energy saving effects.The operation with the color touch screen, simple process flow.

Guangdong Taiantang Pharmaceutical Co., Ltd Coating Machine Unit

Contact us

Email: 918trade@chengdong.com

Add.: No. 367 Yangle Road, Shanyang Town, Jinshan District, Shanghai, China 201508